Robot ranchers will ride herd on wind farms in future, experts say

Hamburg, Germany - Robot ranchers will tend the windswept ranges of sprawling wind farms in the future, according to a team of German robotic scientists.

Hamburg, Germany - Robot ranchers will tend the windswept ranges of sprawling wind farms in the future, according to a team of German robotic scientists.

Wind turbine generators already dot the horizon for miles in any direction in many parts of the world. Tending the mighty windmills has been an arduous task for human technicians. Rotor blade damage is a routine, but annoying problem which entails many man-hours of maintenance.

But now, scientists at the Fraunhofer Institute for Factory Operation and Automation (IFF) in Germany say they are perfecting a generation of robots which will be able to monitor and maintain wind turbine generators on a round-the-clock basis.

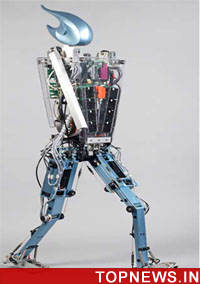

Their latest helper is RIWEA, a robot that inspects the rotor blades of wind energy converters.

Primarily made of glass fibre reinforced plastics, rotor blades have to withstand a great deal: wind, inertial forces, erosion, etc. Until now, humans have inspected wind energy converters at regular intervals - not an easy job.

After all, the technicians must closely examine large surfaces - a rotor blade can be up to 60 meters in length - in airy heights.

"Our robot is not just a good climber," says Dr. Norbert Elkmann, project manager am Fraunhofer IFF and coordinator of the joint project. "It is equipped with a number of advanced sensor systems. This enables it to inspect rotor blades closely."

The inspection system consists of three elements: An infrared radiator conducts heat to the surface of the rotor blades. A high-resolution thermal camera records the temperature pattern and thus registers flaws in the material.

In addition, an ultrasonic system and a high resolution camera are also on board, thus enabling the robot to detect damage that would remain hidden to the human eye.

A specially developed carrier system ensures that the inspection robot is guided securely and precisely along the surface of a rotor blade.

"It is a highly complex platform with 16 degrees of freedom, which can autonomously pull itself up ropes," explains Elkmann.

The advantage of this system is that it can do its job on any wind energy converter - regardless of whether it is large or small, on land or offshore.

The robot always delivers an exact log of the rotor blade condition, and never fails to spot hairline cracks or other potential problems.

It also works day and night without time out for meals or sleep. (dpa)